This project has been designed for traffic density of 3,000 petrol cars per day and 2,000 diesel trucks per day, with max speed of 80 kmph.

On completion, this would be the longest bi-lane road tunnel in the world, at an altitude above 13,000 feet.

Despite challenges of extreme low temperature which affect manpower and machinery alike, the work on Sela Pass tunnel, is progressing at a fast pace.

The Sela pass tunnel, a strategic connect in Arunachal Pradesh, is being built by the Border Roads Organisation (BRO) and the authorities concerned are gearing up to open it by June this year.

While the work is being expedited to construct the approach road to Sela Pass, the lining of the tunnel is nearing completion, with electrical and mechanical work inside the tunnel almost over.

Drill and blast technique for excavation as part of New Austrian Tunneling Method (NATM) is being used for the construction of the tunnels.

On completion, this would be the longest bi-lane road tunnel in the world, at an altitude above 13,000 feet.

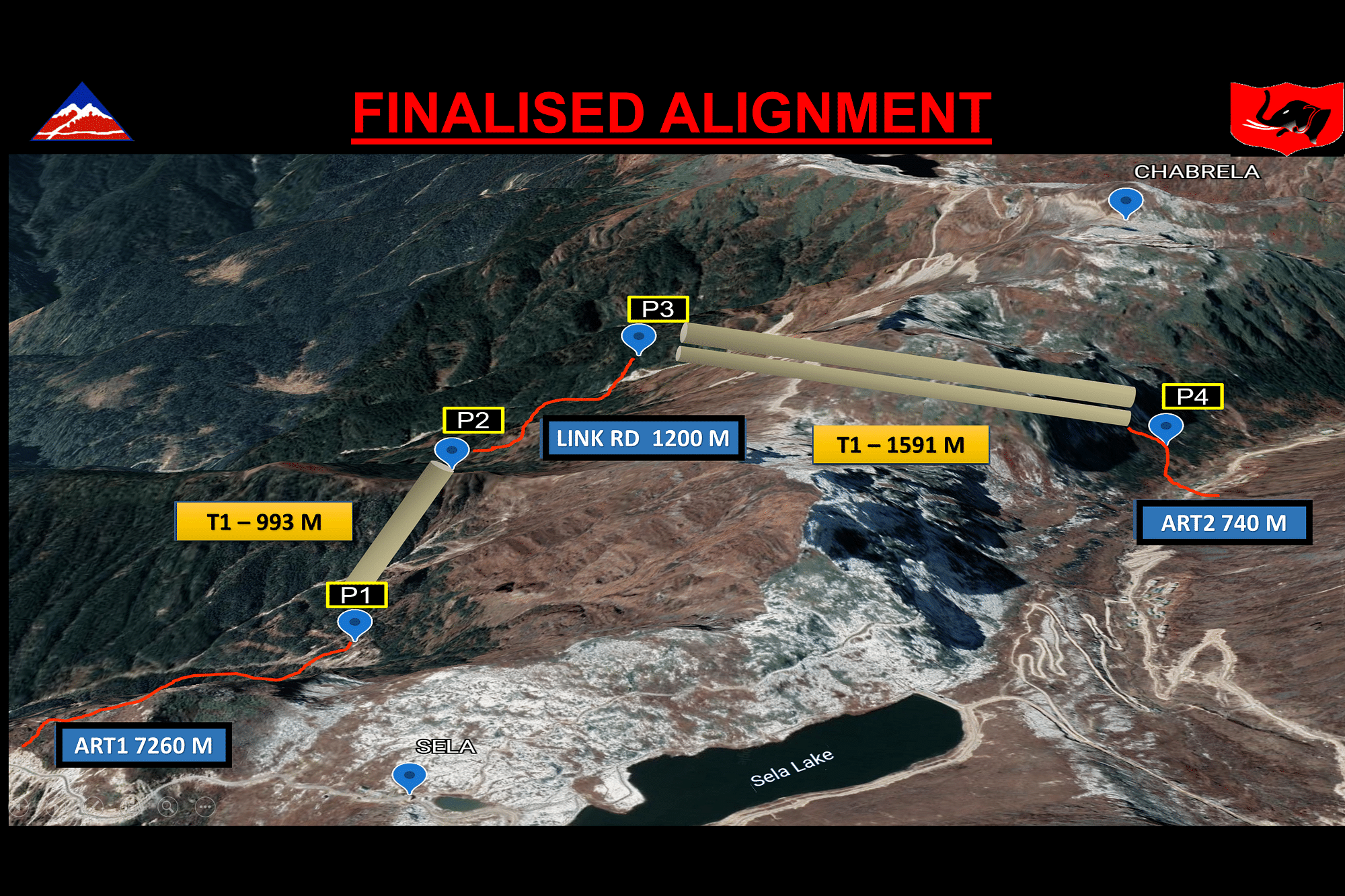

The two tunnels and the 9.075 km approach road is being constructed in the Sela formation of Arunachal Pradesh, on the boundary of West Kameng and Tawang districts.

The lengths of the tunnels and approach roads were subsequently changed based on site conditions.

The current configuration of the project is that Tunnel-1 (T1) is now planned for 993 m length; it was previously 475 m and it is a single tube tunnel.

The Tunnel-2 (T2) is now 1,591 m, which was conceived to be 1,790 m — the T2 tunnel is a twin tube tunnel, with one main and one escape tube.

The main tubes of both T1 and T2 are 12 m wide with overhead clearance of 5.5 m. The escape tube with T2 is 7.26 m wide with an overhead clearance of 4 m, being constructed parallel to the main tunnel at a distance of 20 m and is connected with five cross passages.

This project has been designed for traffic density of 3,000 petrol cars per day and 2,000 diesel trucks per day, with max speed of 80 kmph.

The tunnels are being provided with a state-of-the-art electromechanical system, including jet fan based longitudinal ventilation system, firefighting devices, CIE norms based illumination system and SCADA controlled monitoring systems.

The sanctioned cost for the project is Rs 687 crore including pre-construction cost of Rs 10 crore and four years maintenance cost of Rs 15.63 crore.

Though the project had witnessed significant delays in the days of commencement due to COVID conditions, it has picked up pace and is one of the fastest progressing tunnel works in the Himalayan region, considering the terrain and remoteness.

According to the BRO, the project will go down in the annals of history as one of the most difficult projects executed in the country.

Arunachal Pradesh has a hydroelectric potential exceeding 50,000 MW. In order to tap the electric power generation potential of Tawang Chu River, National Hydroelectric Power Corporation (NHPC) had proposed two mega projects Tawang-I and Tawang-II with a combined potential of 1,400 MW in Tawang region.

Sela Pass, which is the only access to Tawang region, remains closed for heavy traffic during winters due to heavy snowfall for considerable time every year.

The NHPC had planned to bypass this formidable obstacle by constructing a tunnel under the Sela Pass and proposed a 12.57-km-long tunnel, along with an escape tunnel of the same length.

However, the cost of the tunnel project was very high and added significantly to the overall cost of the power projects. There were other local and environmental concerns as well. The projects have still not been cleared for construction.

Consequently, no work on the tunnel was taken up and Sela remained an obstacle for all weather connectivity on this axis.

In 2010, Director General Military Operations (DGMO) proposed tunnels along important areas in the Eastern Theatre to provide all weather connectivity to the border areas, which would enhance operational capability as well as provide succour to the local population.

Eastern Command was asked to undertake the feasibility studies for tunnels at Sela, Bomdila and Nechiphu in Arunachal Pradesh.

Since Sela remained snowbound for about eight weeks in a year, being the highest pass on the axis, it was decided to take up work on Sela tunnel at the earliest.

The tunnel was to be constructed in a strategically acceptable time frame, to offer all weather connectivity to Tawang.

The earlier proposal of 12.57 km tunnel by NHPC, was not only cost prohibitive but also posed serious technical challenges for ventilation and safety, besides the fact that it would require many years for construction.

Keeping in mind the above factors, pre-feasibility for the tunnel across Sela was carried out by BRO in October 2013.

Approval in principle for consultancy service, for the detailed feasibility study and framing up of DPR for construction of two tunnels across Sela Pass on Balipara-Chariduar-Tawang (BCT) road, was given by Defence Ministry on 12 July, 2017 — after a lapse of four years.

A detailed geotechnical assessment of the proposed tunnel area was carried out by GSI in August 2017.

On 14 June 2018, the DPR was submitted by the consultant for further tender action by BRO. Through the DPR, BRO proposed two tunnels of 475 m and 1,790 m length with approach roads length aggregating to 9.075 km.

This alignment was decided in such a fashion that the alignment remained below the snow line and allowed for all-weather passage of vehicles without major challenges of snow clearance.

The alignment saves a distance of more than 8 km and cuts down the travelling time by an hour, while obviating the treacherous Sela Pass climb — which is prone to many accidents due to the peculiar topography.

Key Plan Of Sela Tunnel Project

The foundation stone of Sela Tunnel was laid by Prime Minister Narendra Modi on 9 February, 2019. Project Vartak of BRO was entrusted to oversee the construction.

Construction commenced on 1 April, 2019 — with the first blast taking place at Nuranang side Tunnel portal on 31 October 2019. There was an initial delay in mobilization of resources due to the COVID-19 pandemic.

The contractor struggled to import the requisite equipment and could not gather labour required to run the project at desired pace.

Importing skilled labour from other states during COVID restrictions proved to be a major hurdle in the first year of construction, besides the lack of adequate specialist equipment.

On 15 January, 2021 first blast at T1 from the Baisakhi side was undertaken by Lt. General Rajeev Chaudhry, directorate general border roads (DGBR) after giving on site directives. This tunnel was then excavated within a year of the first blast.

Challenges Faced And Solutions

Sela Tunnel is being constructed at an altitude more than 13,000 feet above mean sea level (MSL), across the Sela pass which is located more than 250 km away from a rail head.

The area witnesses very high rainfall and heavy snowfall during the winter months. The temperatures drop up to minus 20 degrees which leads to drying up of all water sources, posing technical issues for concrete works and hampering the efficiency of manpower and machines alike.

The distance of the region from a proper township and lack of a stable mobile network has its adverse repercussions on the persons deployed on the project work site.

The Himalayas are one of the youngest mountain ranges in the world and owing to the subduction phenomenon, tunnel construction in the Himalayan region is probably the most challenging construction activity in the field of civil engineering.

Water is required on a tunnel construction site for drilling, concrete works and other miscellaneous activities. However, natural sources get frozen in the winter months and sometimes during the night, even in summer months.

This posed serious challenges for progressing the work at the desired pace. The issue was resolved by making sumps inside the tunnel and keeping the water in circulation, to prevent freezing.

Some artesian sources were identified within the tunnels to tap water as they were perennial due to the inherent rock mass heat.

According to the BRO, the site work in these months was carried out by organising four shifts of six hours each. The workers were provided special clothing, work warming regimens, local heating arrangements on the working sites for better efficiency and proper health.