The story so far: Last week, the government announced setting up of mega textile parks, spread across at least 1,000 acres, in seven States – Tamil Nadu, Karnataka, Telangana, Madhya Pradesh, Maharashtra, Gujarat, and Uttar Pradesh- under the PM Mega Integrated Textile Regions and Apparel (PM MITRA) scheme.

The PM MITRA Scheme, announced in 2021-22 aims to develop integrated large scale and modern industrial infrastructure facility for the entire textile value chain, from fibre to fabric to garment and is expected to generate investments worth Rs 70,000 crore and creation of 20 lakh jobs.

The proposed megaparks will have plug-and-play manufacturing facilities and all the common amenities, including effluent treatment plants, accommodation for workers, skill training centres and warehouses. The park is envisioned to attract investment from companies looking to scale up, requiring integrated manufacturing facilities in one location.

Based on clusterisation approach, the Rs 4,445-crore scheme which would be the biggest-ever initiative for infrastructure in textile and apparel sector is a giant leap over its predecessors and aims to augment the export potential of the sector.

Clusterisation

Simply put, industry clusters are geographic concentrations of related industries.

Clusters consist of companies, suppliers and service providers, as well as government agencies and other institutions that provide raw materials, research and technical support to an industry.

For example, Datang Sock Cluster, located in Zhejiang Province in China is known as the “Capital of Socks”. The cluster produces 27 billion pairs of socks every year worth 75 billion yuan ($11.14 billion) every year, accounting for 70 per cent of the national market and 35 per cent of the global market.

The town which was earlier a small rice farming village has metamorphosed to a place with the presence of the total value chain of socks business aided by Government which provided land, gave tax benefits and developed infrastructure and transportation network needed to move products quickly to the market.

Key Features

The Ministry of Textiles in 2016 had got its scheme on Integrated Textile Parks (SITP) reviewed by Wazir Advisors with a view to gauge the impact of clusterization on production, employment and success.

The report stated that successful clusters share following common attributes:

- Large scale of operations: Most of the clusters have units which are large in scale to leverage economies of scale for sourcing, utility consumption, overheads, and marketing.

- Presence of integrated value chain: Successful textile clusters, for example, have units across the value chain, starting from fibre to finished goods along with a well-developed support service such as financial institutions, logistics providers, approving authorities, etc. within the area itself.

- Well-developed common infrastructure: The Cluster provides reliable common infrastructure to user industry such as connectivity to ports & expressways, uninterrupted power and water supply, ready-to- use factory sheds, testing labs, R&D centres among others.

- Ease of doing business: The Government frames more flexible rules and regulations for businesses operating in these clusters, such as single window clearances, liberal work permit policy, easier financing options, etc.

- Special fiscal incentives: Many clusters exempt businesses from various local taxes and import duties.

Absence of Integrated Value Chain

The textile sector has benefited from different programmes in the past, the most recent being the Scheme for Integrated Textile Parks (SITP) launched in 2005.

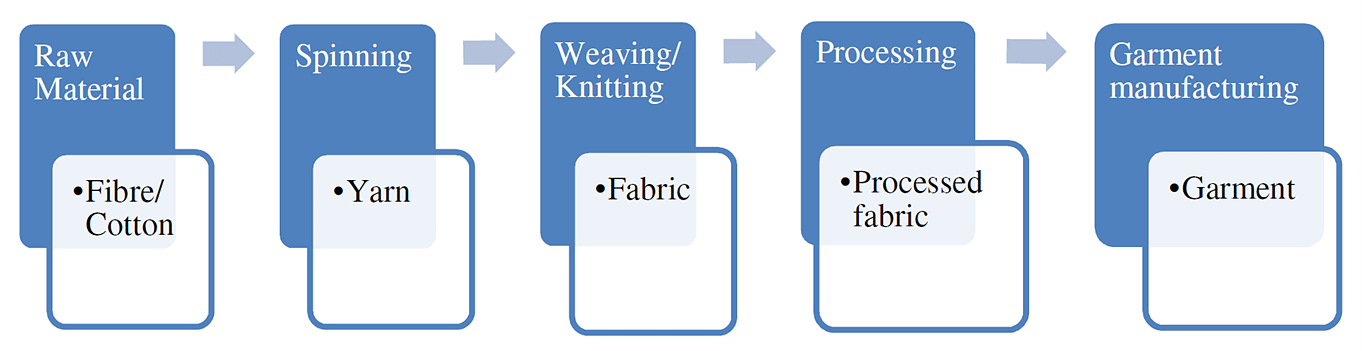

The main objective of the SITP Scheme was promotion of industrial clusters and development of Integrated Textile Parks which should ideally integrate maximum components of the textile value chain as depicted in the following chart:

However, a Comptroller and Auditor General (CAG) of India report tabled in Parliament on 27 March, disclosed that the scheme has fallen well short of all of their targets.

Of the 98 integrated textile parks sanctioned by the government since 2005, only 26 parks (26.53 per cent) had been considered as ‘completed’ as of February 2022, with 30 parks (30.61 per cent) still under construction and 42 parks (42.86 per cent) having been cancelled.

A major issue highlighted in the CAG report is that very few Parks are fully integrated Textile Parks (from fibre to finished goods) and have only one to two segments of the value chain.

The absence of key components of the integrated textile value chain in a park i.e., spinning, weaving/ knitting, processing and garmenting means these parks do not provide any benefit of value chain and promotion of industrial clusters which would have led to reduction of production costs.

Secondly, the existing SITP Scheme does not incentivize large scale park development and as a result, the scale required for global competitiveness has not been achieved in textile parks.

PM Mitra

This is where the PM Mitra scheme comes into the picture, the differentiating factors being the emphasis on large-scale production and provision of plug-and-play manufacturing centres.

These parks are envisaged to be located at sites which have inherent strengths for the textile industry to flourish and have necessary linkages to succeed.

Under the scheme, each park will be developed by a Special purpose vehicle (SPV) having a 51 per cent equity shareholding of the State government and 49 per cent of the Centre. The State governments will provide the land, be part of the SPV, and give the required clearances.

The Central government will disburse Development Capital Fund of Rs 500 crore in two tranches for each of the seven facilities. This is for the creation of core and support infrastructure such as effluent treatment plants, accommodation for workers, skill training centres and warehouses.

It will also give a Competitive Incentive Support of Rs 300 crore per park to be provided to the manufacturing units.

Way Forward

In a developed cluster, as the firms are closely related, they benefit by sharing technological and marketing knowledge, and learning effects may be easier to achieve because it is easier to monitor what the neighbours do and learn from their successes and mistakes.

Mega Parks proposed to be set-up under the PM MITRA Scheme would reduce logistics costs by housing the entire value chain at one location which is one of the critical focuses of clusterisation.

Further, these parks can improve the price competitiveness right from the raw material stage and also help meet the sustainability and traceability demands of international buyers.

Inspired by the Prime Minister’s 5F vision – Farm to Fibre to Factory to Fashion to Foreign – the PM MITRA scheme is a major step forward to strengthen the global position of India and improve the textile exports which have remained stagnant at around the $40-billion mark over the past four years, the aim is to achieve $100 billion in exports and target a domestic business of $250 billion by 2030.